2 Phase NEMA24 Brake Stepper Motor 1.8 Degree

Bipolar motors

Bipolar motors have a single winding per phase. The current in a winding needs to

be reversed in order to reverse a magnetic pole, so the driving

circuit must be more complicated, typically with an

H-bridge arrangement (however there are several off-the-shelf driver chips available

to make this a simple affair). There are two leads per phase, none

is common.

A typical driving pattern for a two coil bipolar stepper motor

would be: A+ B+ A− B−. I.e. drive coil A with positive current,

then remove current from coil A; then drive coil B with positive

current, then remove current from coil B; then drive coil A with

negative current (flipping polarity by switching the wires e.g.

with an H bridge), then remove current from coil A; then drive coil

B with negative current (again flipping polarity same as coil A);

the cycle is complete and begins anew.

Static friction effects using an H-bridge have been observed with

certain drive topologies.

Dithering the stepper signal at a higher frequency than the motor

can respond to will reduce this "static friction" effect.

Product description

Automatic assembly line

Automatic assembly line, improve production efficiency, low cost

without human operation, one line down intelligent mechanical

automatic assembly

Strictly control the production of parts to improve the quality of

parts

Automatic machine operation, stable automatic work, high processing

efficiency.

Mechanical size 100% meet the requirements, to ensure that there is

no greater error in the use process

Online testing of technical parameters to ensure the consistency of

data product parameters

Specifications

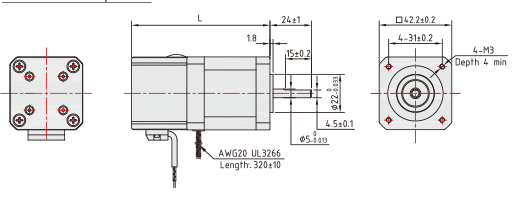

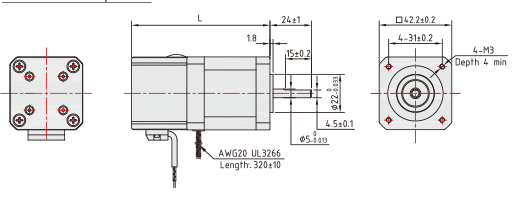

| Model | PST60H268-4L40M | PST60H286-4L50M |

| Holding Torque | 2.2N.m | 3.2N.m |

| Related Current | 4A/Phase | 5A/Phase |

| Resistance | 0.5Ω/Phase | 0.4Ω/Phase |

| Inductance | 1.2MH/Phase | 2MH/Phase |

| Inertia | 340g.cm² | 690g.cm² |

| Black Torque | 1.3N.m | 1.3N.m |

Radial Load&Axial Load

| Motor Size | Shaft Diameter (mm) | Radial Load (N) | Axial Load (N) |

| Distance from Mounting Surface (mm) |

| 5 | 10 | 15 | 20 | 25 | 30 | 35 |

| NEMA8 | 4 | 15 | 12 | | | — | | | 3 |

| NEMA 11 | 5 | 50 | 35 | 25 | | — | | | 5 |

| NEMA 14 | 5 | 50 | 35 | 25 | 20 | — | — | — | 10 |

| NEMA 17 | 5 | 50 | 35 | 25 | 20 | — | — | | 15 |

| NEMA 23 | 8 | 270 | 180 | 130 | 100 | 90 | | — | 20 |

| NEMA 24 | 8 | 200 | 135 | 100 | 82 | 58 | — | — | 30 |

| NEMA 34 | 14 | 620 | 550 | 480 | 390 | 340 | 290 | 260 | 60 |

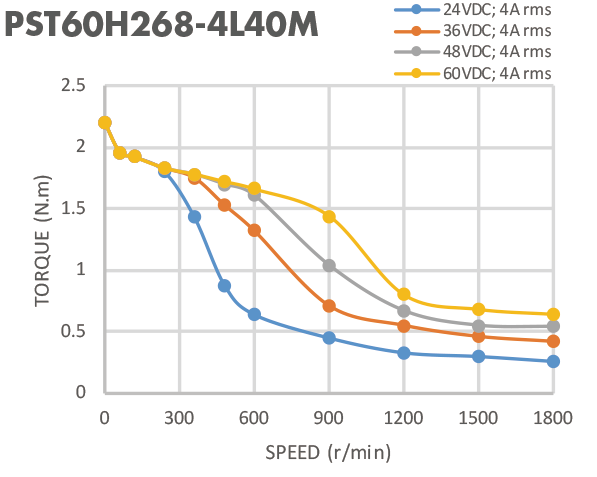

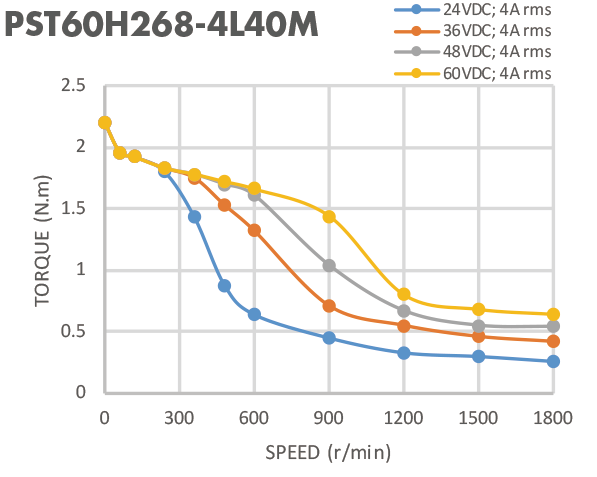

Speed/Torque Characteristics(Reference Value)

Tips: How to overcome the vibration and noises of 2-phase hybrid

stepper motor when rotating at low velocity?

The vibration and noise of the stepper motor rotating at low

velocity its the intrinsic defects, which can be generally overcome

by adopting following schemes:

1. If the stepper motor works at resonance region, the resonance

region can be evaded by changing mechanical transmissions such as

velocity ratio.

2.Use subdivided driver, which is the most common and simple

method.

3.Replace for the stepper motor with smaller stepping angle, like

3-phase or 5-phase stepper motor.

4.Replace for AC servo motor, which can nearly overcome vibration

and noise, but the cost is quite high.

5.Add magnetic damper to the shaft of motor, such product has been

available in the market, but the mechanical structure is changed a

lot.